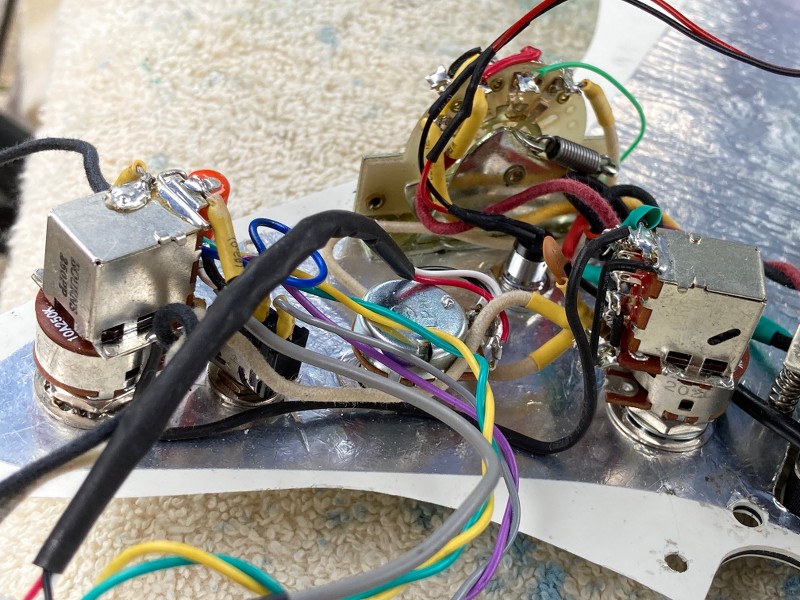

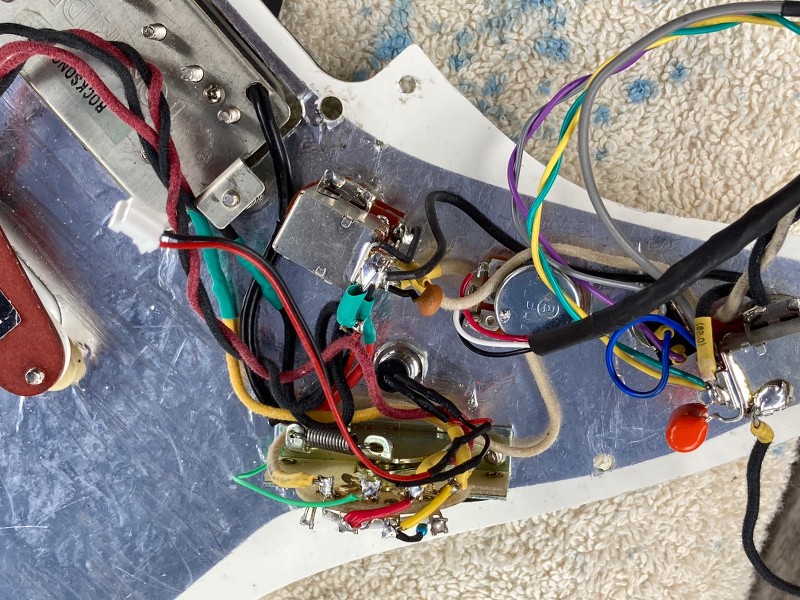

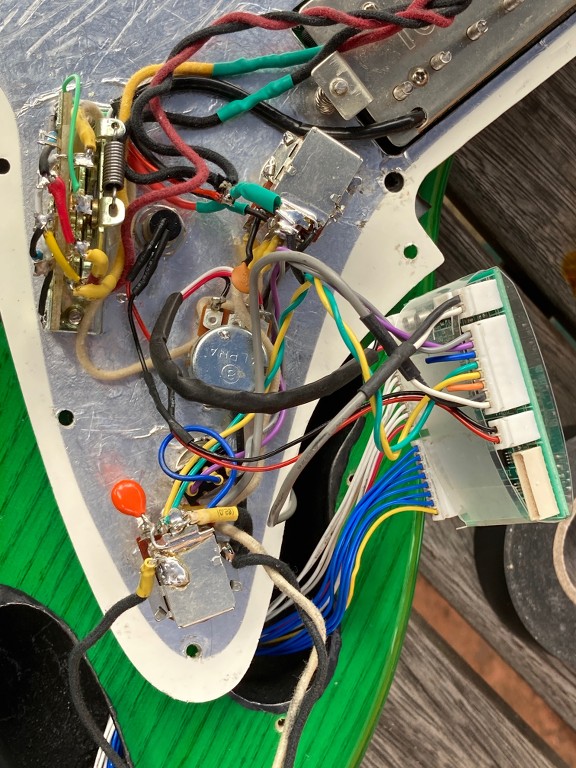

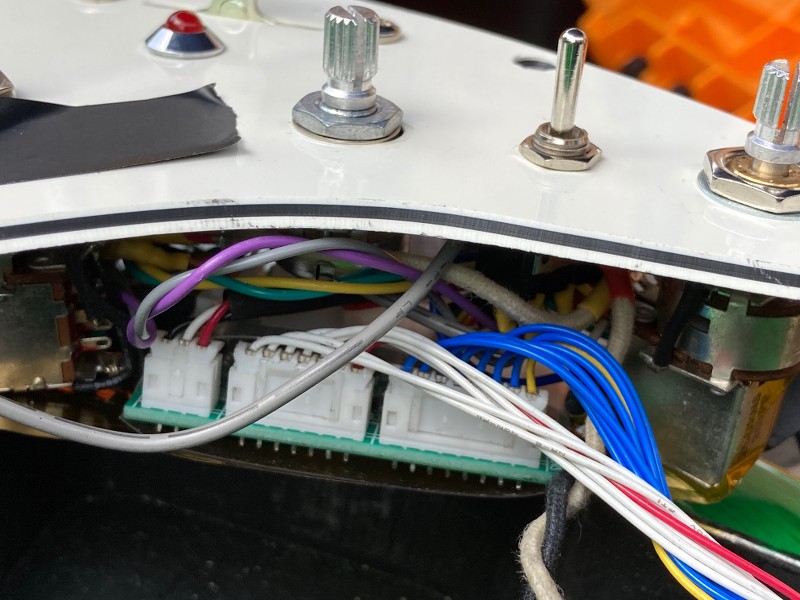

The finish wasn't quite as hard as it should have been, as that masking tape left a faint pattern of dots behind when removed it. So I left it a few more days. Today I re-sanded and re-polished it, and have started to fit bits to it. Still to solder the wiring, but I'm feeling a bit under the weather the past few days and not at my most mentally alert, so am waiting until whatever I have passes and am thinking clearly. There's a lot of wiring to fit in a small space.

Reply With Quote

Reply With Quote