Hello, everyone!

Firstly, it's awesome to see such a supportive community of people passionate about a noble activity such as building musical instruments! I've been reading and learning as much as possible here before embarking on this first build, and I hope I can also get some tips on this first build.

I must admit I have negligible experience with carpentry and electrics, so this is already being a steep learning curve for me. And it's also quite exciting.

I got my DGM-12 kit and let the wood aclimatise for a few days.

I've inspected the parts and done a mock build, and here are my findings:

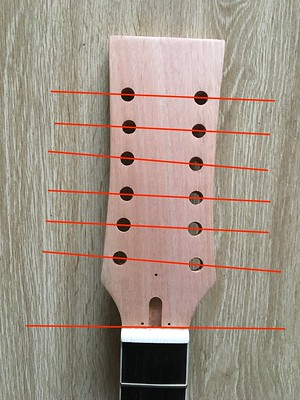

1. There is a knot in the head that seemed to have been filled, I wonder if that would be an issue with the string tension over time? Otherwise I'm happy to put it down as "added character" to the guitar.

2. There's a section of the fretboard that seems to have been sanded by accident, so whatever finish there was there was removed. I imagine that would be just a matter of applying it again and it would match the rest?

3. There's a bit of glue in the joint at the top (would sand paper take it out?) and a couple of gaps at the bottom - which I intend to fill with Timbermate.

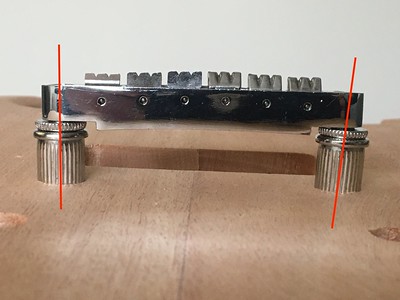

4. My biggest concern though is how the bridge saddle holes don't seem to match the width of the saddle itself. To make the saddle fit the poles without them being pushed in all the way in for the dry build, you can see how the poles are off-centre. I've seen this in another build here (Simon's beautiful double SG-build) and I don't know if it's something I'll have to deal with myself or if it warrants a replacement from Pit Bull. What do you guys think? I'm afraid I don't have the tools needed to drill a new hole if this one needs to be filled - I'd have to get some help from a friend to do it.

Thanks in advance!

Reply With Quote

Reply With Quote