I wired up the Tele last night. It was pretty straight forward, tested it by touching the pups with a screwdriver, it made the right clicks at the right time.

Sat down last night and thought, damn I forgot to shield the cavities. So, today I got the copper shielding tape out, shielded the cavities (pickup cavities, control plate cavity & input socket). I am waiting for a new pickguard to come home so haven't obviously shielded that yet.

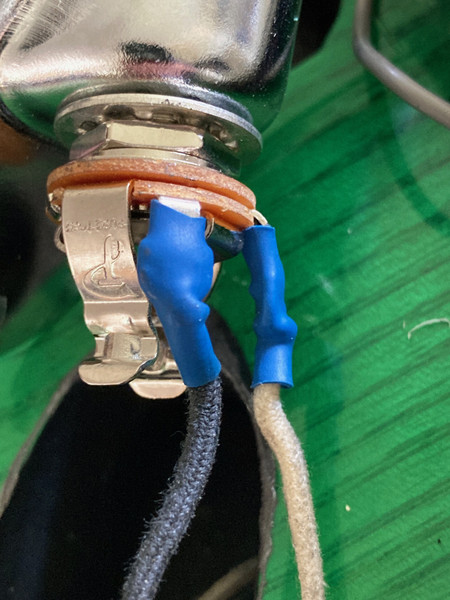

Again, I tested, it all worked as expected, (if anything a bit noisier), until I screw the input socket into the cavity. It works right up until I tighten it up. As soon as the last few turns of the screws happen it cuts out - silence.

Is something making contact that could cause this issue? I tried moving the nuts as far out/in as possible but it didn't change anything.

Should the input socket be shielded? Is it anything to do with the pickguard being missing?

The bridge is grounded but when testing, I also noticed that when I touch the bridge it results in the same clicking sound as when I touch the pickups? All a bit weird??

Happy to upload images if that helps.

Any advice, as always, is much appreciated. Thank you.

Reply With Quote

Reply With Quote