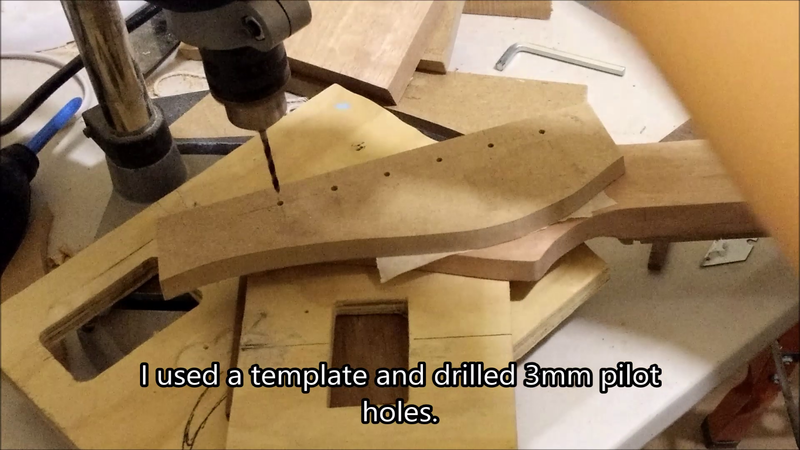

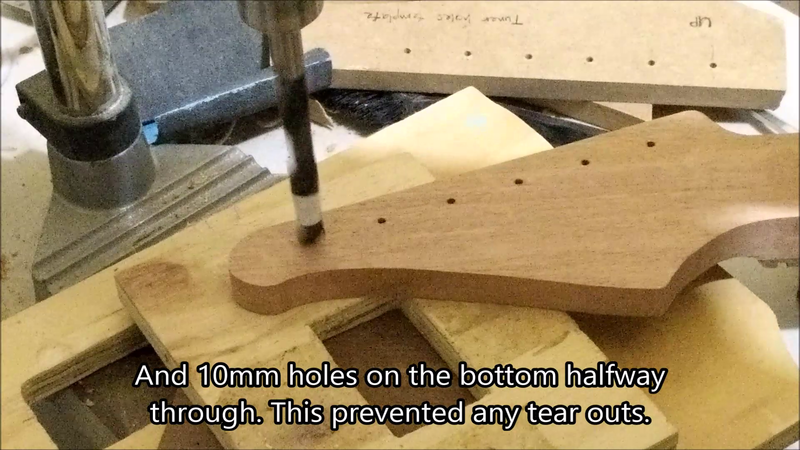

Then I drilled the tuner holes. I made my own tuner hole template and used it as a guide.

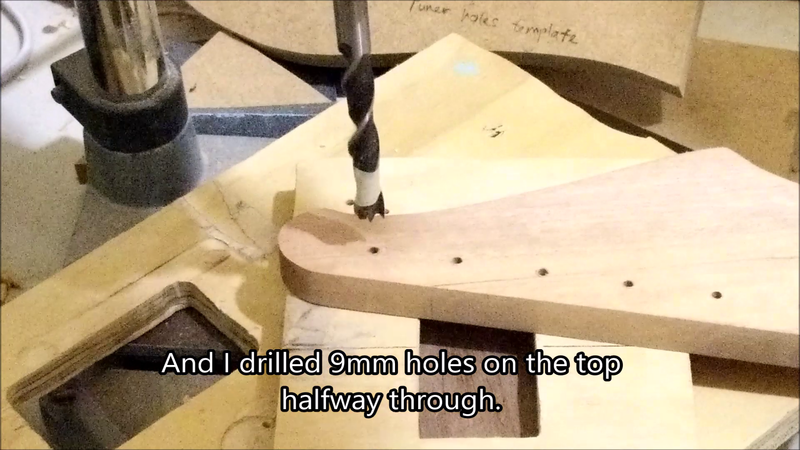

Then I drilled 9mm holes on the top...

And 10mm holes on the bottom.

I had no tear outs like this, but I guess if you used just a 10mm bit and put a piece of scrap wood underneath you wouldn't get tear out too. I did it this way because I wanted the top side where the nut screws into the post to be more snug. 10mm holes made it too loose and I didn't like that.

In the end, I had perfectly aligned holes. unless someone has a eagle eye and is able to spot a tiny difference, I'm happy with it so far!

Reply With Quote

Reply With Quote