In regards to the finish. Lots of people like tru oil. For me personally after having used it once, I do not intend to ever use it again. I'd rather spray with lacquer with a spray gun, even with my lack of ability.

In regards to the finish. Lots of people like tru oil. For me personally after having used it once, I do not intend to ever use it again. I'd rather spray with lacquer with a spray gun, even with my lack of ability.

Build #1 - TLA-1Q

Build #2 - Scratch Thinline Tele

Build #3 - Scratch Rickenbacker 330/12

Build #4 - Scratch All Aussie Timber Strat

Build #5 - 1st Violin/Fiddle

Pedal Build #1 - Aion Gale

Pedal Build #2 - Aion Aurora

Iíve been practicing with a rattle can of Watco crystal clear (nitro) lacquer and really like it - itís a great spraying can and it seems to go on effortlessly with no need for touch-ups. I tried Deft water based acrylic and find it to be too much time fixing imperfections. The local Wood Craft store has Mohawk instrument (nitro) lacquer and also Mohawk vinyl sealer. The lacquer is same ingredients as Watco so I was going to try the Mohawk vinyl with Watco lacquer.

That said, I read about natural finishes in-line last night and a combination of shellac base coat with (nitro) lacquer top coat might give me the depth, ease, and protection Iím after.

LMII has a comment that if you were to go into business, nitro is the wise choice because itís an industry standard. So even if Iím not in business it seems like a good place to start.

The color for the back will be tricky since Iíve never stained or finished mahogany. Maybe I can find a similar enough test piece locally. The inspiration pic I posted has a much cooler brown (not many reds at all) so trying to match is probably not the right approach. I guess with a natural top pretty much anything should work though.

I really like the grain on the back of the guitar, but not the sides. In the back of my mind Iím kicking around the idea of a binding or natural faux binding and doing something different on the sides to hide the grain. Itís just a thought at this point.

I also am realizing I shouldnít go to crazy trying to make the guitar into something it isnít.

Last edited by Joe Garfield; 19-05-2020 at 09:53 AM.

*Pictures may be rotated due to my proximity to the equator.

Today I ordered black Gotoh bridge hardware. Since the guitar is already drilled for Tunomatic I donít have the option of using a Benedetto style tailpiece. But I think a black bridge and stop bar will give a similar visual effect to the inspiration guitar. The 2 Knobs will be black and the 3 switches will be nickel hardware with black toggles. Black pickup surrounds and nickel pickup covers. Iíll change the nut for a black Graphtech Tusq nut, and the machine heads will either be light weight black, or mini nickel with ebony buttons.

The inspiration again for reference:

Last edited by Joe Garfield; 19-05-2020 at 09:48 AM.

*Pictures may be rotated due to my proximity to the equator.

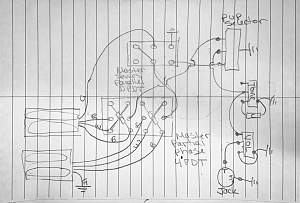

IĒm not a big fan of normal (individual) series/parallel switching low impedance humbuckers, but I do like playing with tone. Entwistle has a diagram for partially phasing individual humbuckers which is supposed to sound better. Also, the Languedoc guitar Iíve been referencing has a Ďmaster series/parallel switchí and I found that intriguing. So I came up with a way to implement both. I posted this is a separate thread in the wiring forum (https://www.buildyourownguitar.com.a...ad.php?t=10478) but itís part of this guitar, so here it is (I might have the pups backwards and IDK if anything else is wrong with it yet.)

*Pictures may be rotated due to my proximity to the equator.

Another thing Iím trying to figure is how to touch up binding gaps without affecting finish options. If I use CA it might show up if I were to stain the guitar. I ordered some PVC binding to make an acetone slurry though Iím not sure thatís the right approach either. Maybe just heat and straight acetone?

*Pictures may be rotated due to my proximity to the equator.

You could stain and then repair the binding. Though acetone/binding slurry applied with a toothpick could work if you are careful and use a magnifying lens. Alternatively some grain filler should fill the gaps and take up any stain applied.

Too many options available!

My next build is going to be binding free if I can help it! Ah, the simplicity

Mantra: No more pedals, must finish BlueyCaster...

Disclaimer: I haven't done woodwork since high school, and wasn't really paying attention at the time ...

I totally missed the thought of fixing the bindings after staining. That might be the best approach, then I could use almost any adhesive I choose.

The wood is the right shape and the binding should be adjusted to match it, so I ruled out any filler other than more binding (w/ acetone.)

*Pictures may be rotated due to my proximity to the equator.

I have an idea for stain but it will be a surprise. Iím now 50/50 stain vs natural.

*Pictures may be rotated due to my proximity to the equator.