All the advice I have ever seen suggests that you need the drips, runs or sags to be completely dry/cured before sanding. I think that is the safest thing to do.

Some finishes cure faster in heat, but it could just as easily cause a different problem, so I would not do that without consulting the mfg.

I have been known to do things that are stupid, like using the razor blade to very carefully cut off the top of a big drip to get it to cure faster. I won't say this has never worked, but I will say it can go either way.

I have almost exclusively used a water-based, brushed on clear, and I put more coats on than the mfg recommends. It gets the occasional drip. The mfg says it needs 4 weeks to fully cure. That is a long time to wait to sand out a drip. So I will sometimes try to do it a little sooner than that. If I see it balls up when you sand, STOP and wait.

If the drip is not too thick, had dried clear and doesn't have a dust spec* or something in it, what I will sometimes do (also a little risky) is just keep adding finish, until I have the full set of coats. In my finishes there are brushstrokes that need to be sanded out anyway, so drip is not radically different than other imperfections in my finishes.

Once the full set of coats has fully cured, then I deal with the drips or other imperfections. The thing I like best about this method is that the finish is considerably flatter--including the drips--after waiting 6 weeks for the finish to cure than it was when the drip was wet.

I don't know whether this is an idiosyncrasy of the water based finishes I use. Maybe the result would not be as good with other kinds of finishes? Also it does not really cut down on the dry time before getting rid of the drip. It just allows you to keep adding finish while you wait for it to cure.

Hopefully others will chime in with better reasoned advice.

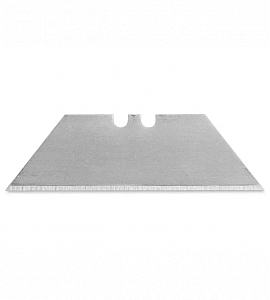

With regard to the razor blade. I was definitely referring to the "American" type. We have what you call the "Indian" type too...but only for shaving. I would worry that it might be too flimsy for this usage. If you can't find the American-type razor blade how about a utility knife blade?

Reply With Quote

Reply With Quote