Thanks guys, gives me some ideas to work with.

I have some old yoga/exercise mats that the wife no longer uses, while they are bright blue and red, I could easily hide them from view in the tight cavities.

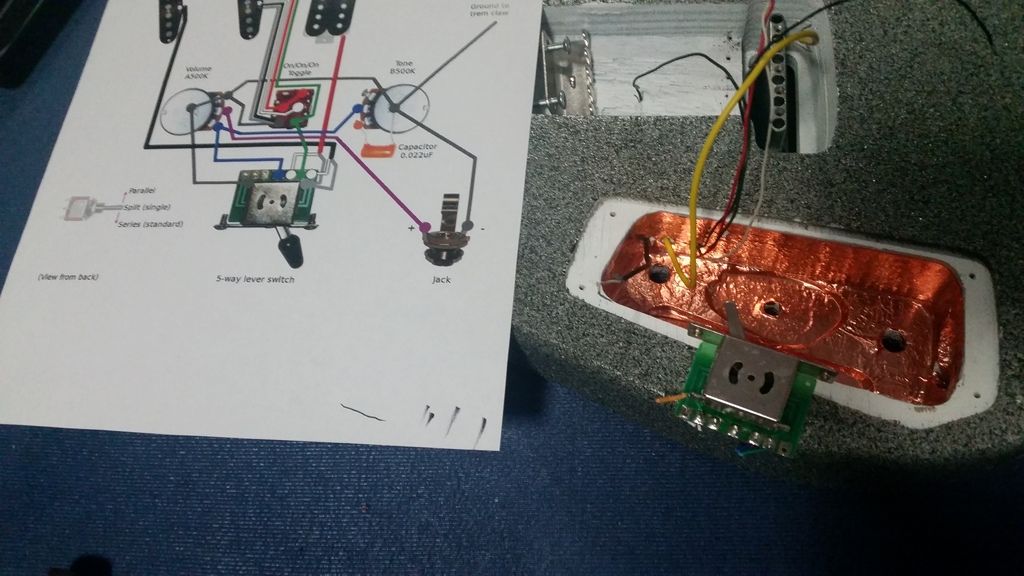

Tonight I had Brass band practice, so I'll start shielding and wiring tomorrow night!

Reply With Quote

Reply With Quote