Almost there...

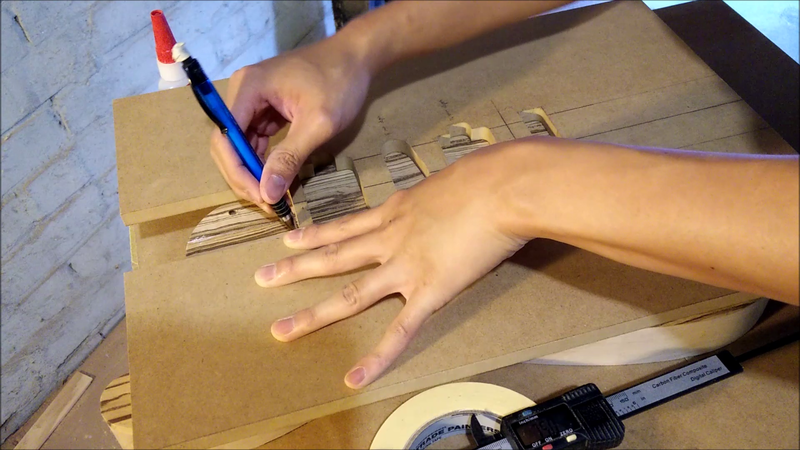

I always stay clear of the line, at least 5mm away, because you don't know if the blade will wander underneath. You can always remove wood but not add wood back.

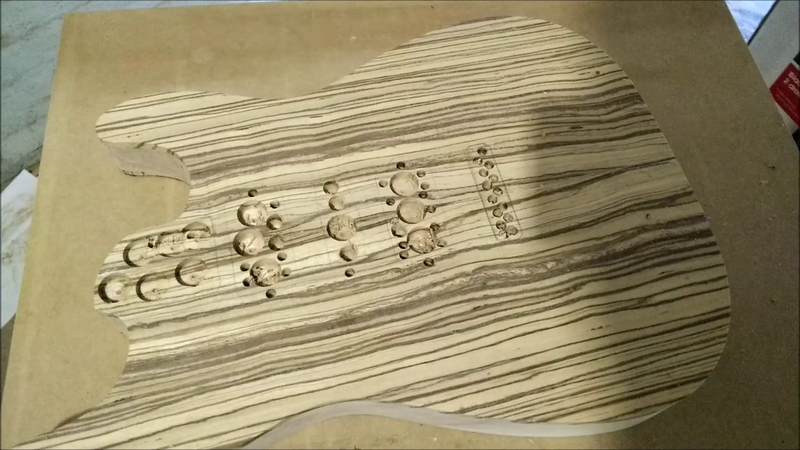

Then I made sure the surfaces were flat before gluing. I stuck 4 pieces of 60 grit sandpaper to large piece of mdf as a huge sanding block. Got to make do without expensive tools!

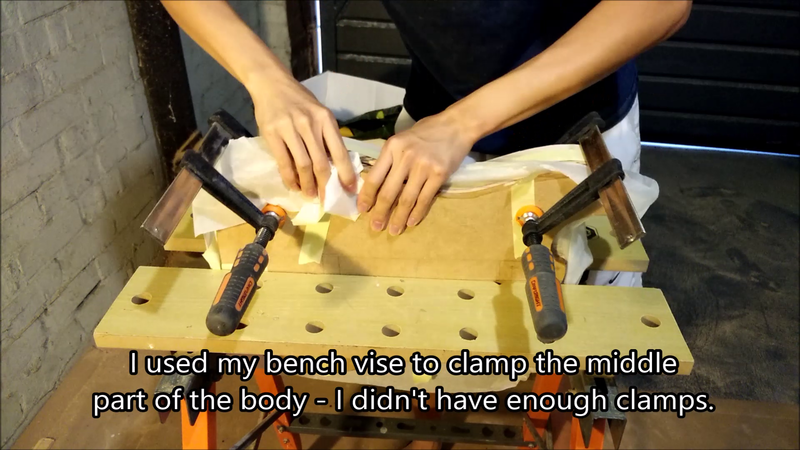

Spam as much glues as you can! The glue gets soaked in real fast and if you don't work quickly it can solidify and you'll be in trouble. Looking back, I wish I had put more glue!

Reply With Quote

Reply With Quote