I picked up this old Regal parlour guitar yesterday for £100 (approx. AUD$190/US$129) through Facebook Marketplace. I don't know quite how old it is but there are pictures of similar ones on the web giving dates in the 1930s and 1940s. There is no serial number or internal maker's sticker at all.

As Regal proper shut up shop in 1954, it's certainly won't be any younger than that. Regal were best known for making resonators (up until 1941 when like many other woodworking companies they switched to war work for the duration). In the 1930s Dobro licensed their designs to Regal, so there are Regal Dobros out there. Regal also made quite a range of small-bodied guitars, tenor guitars and ukuleles, often for other companies to sell under their own brand name. After 1954, the Regal brand was first bought by Harmony and later Fender. The brand name had gone quiet by 1965 but was resurrected in 1987 for a line of Asian-made resonators that continues to this day.

There's no adjustable truss rod, but the neck is pretty thick to make up for it and the neck looks to be pretty straight. Nut width is 55mm, so slightly wider than current norms. It's got a 24 1/4" scale length, so is only a bit shorter than standard. The top E string was buzzing slightly along its length, but it had one very loose string and it wasn't in tune. It certainly needs new strings and once these are fitted and brought up to correct tension, then I'll know if it needs a new higher saddle or not. The neck is flat (rather than radiused). The frets are slightly indented and don't look particularly flat when looking along the neck, so it may well get a level.

The nut (bone) fell off when I removed the strings. The front (fretboard) edge of it is chipped by the B and high E slots, and whilst I could sand it down to remove the chipped area, it might then be a bit on the thin side to be stable, so I think I'll fit a new nut.

I've now polished the frets and the fretboard is currently soaking up a good application of lemon oil. It was rather dry.

Looking at the grain pattern, it's certainly a solid top and back. Because the sides are a solid black, I can't determine whether they are solid or laminate. There is a thin crack running halfway across the upper rear bout. The crack is a lot shorter on the inside than the outside, so it's 's not too badly damaged. But the cross-braces on both sides of the soundhole have come away from the top on the upper sides, presumably as a result of whatever knock put the crack in the top, so they'll need gluing back.

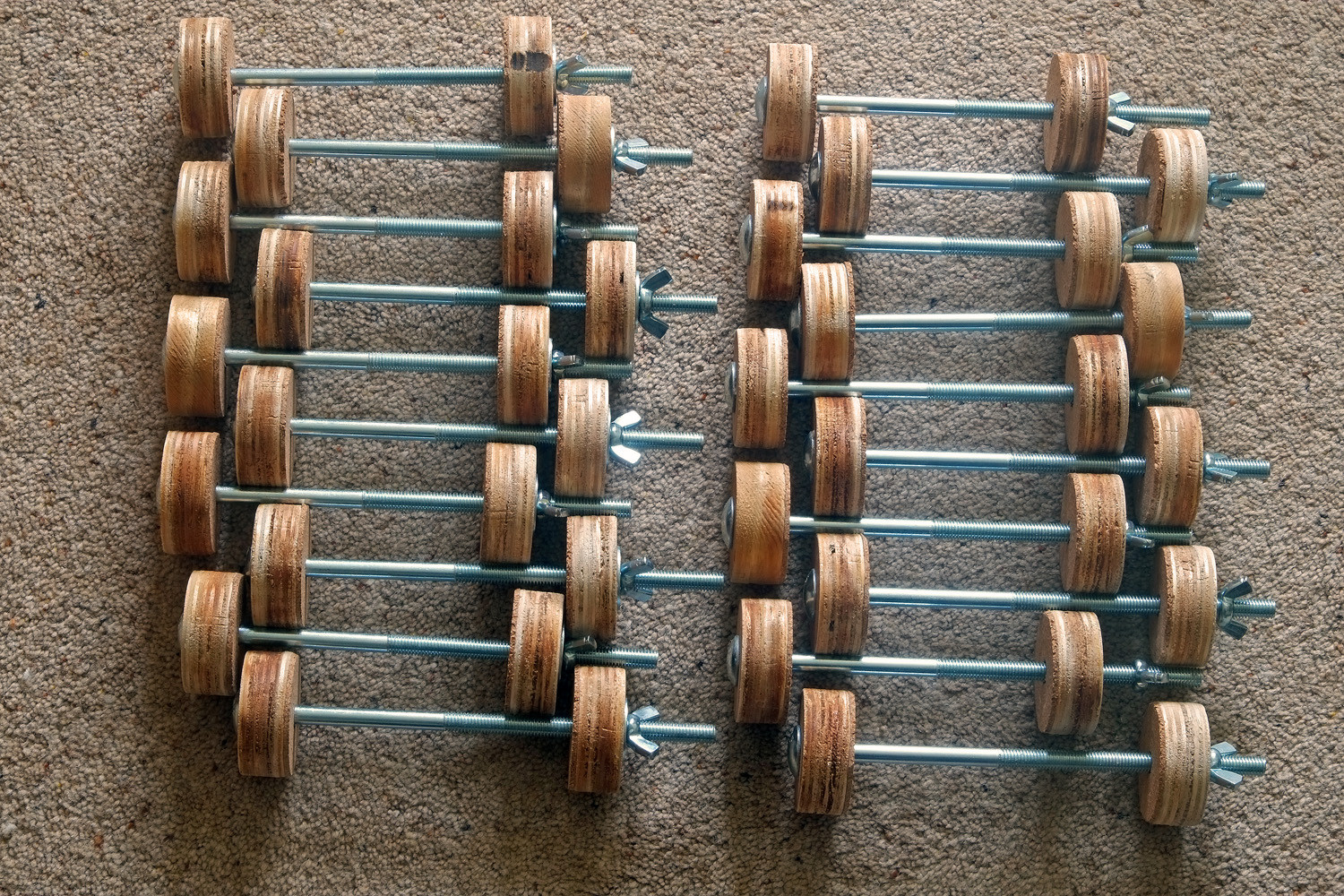

Another check showed three of the rear braces are not fully attached - one is only hanging on at the end. So it looks like I'll need to knock-up some internal 'go bars' to apply pressure when gluing them back. So certainly no restringing it until the bracing is secure again.

I've also noted that also need to get some tuner bushings for it as it should have them, and the tuning pegs are rattling around a fair bit as a result. The push-in ones do fall our rather easily. Had to get some for the 1965 Harmony Rocket I did up a few years back. I may get a new set of tuners for it as I think some of the current ones are probably too loose with too much backlash in the gearing to hold tuning well. Luckily the 3-on-a-strip tuner post dimensions has stayed constant throughout the ages (1/4" post diameters and 35mm between post centres) so I can drop a more modern strip in without any issues. I'll obviously keep the originals safe.

It's not my oldest instrument; that's a 1903 Italian-made bowl-back mandolin that I got given and restored in the late 1970s. But that's got such a thin neck that I can't really play it, and the bowl-back makes it even harder to play. But it's certainly now my oldest guitar.

Reply With Quote

Reply With Quote