Inspired by my ES-1/ES 330 style build, my mate Mark picked up an ES-1 kit from Pit Bull when he was visiting Perth a couple of years ago. However he'd only recently moved house which has been a bit of a project and taken up all his spare time, so the kit was languishing in its box. So I've offered to put it together for him.

There were some dirty fingerprint marks on the top, which I found a bit worrying, and a 2cm x 1cm raised smear of glue on the rear.

But a wipe-down with white spirit didn't show any glue marks on the top and removed the fingermarks.

Splintering on the veneer around the upper horn and a strange grey mark that seems to be ingrained in the wood and not on the surface:

The usual soft core wood cut with a blunt routing bit:

But a bit of sanding has got that looking reasonably presentable.

Mark wanted a blue guitar, along the lines of Daphne blue, so I said I'd have a look at the top to determine if it was good enough to try staining that colour or whether we went with a solid finish.

Wetting it with white spirit (I'd run out of turps and methylated spirit) showed what I'd expected from the look when dry:

The flame pattern was only strong in a couple of areas like the lower horn. The photo improves the actual contrast which was far less. So it was decided to go with a solid colour.

So it will be this blue:

I then had a look at the neck and the neck angle once fitted, as too shallow a neck angle has been a persistent problem on a lot of ES-1 kits.

The neck wouldn't fit in the slot, primarily due to this thick mass of glue on the side of the block (and a smaller amount on the other side):

A few minutes work with some sandpaper removed the glue and got the neck fitting about as well as any of the PB kit set necks fit.

An annoying chip out of the end of the underside of the fingerboard:

But at least the choice to go with a solid colour means that I don't need to worry about glue marks, and I can fill in the small chips and cracks without having to try and match things up so they aren't noticeable.

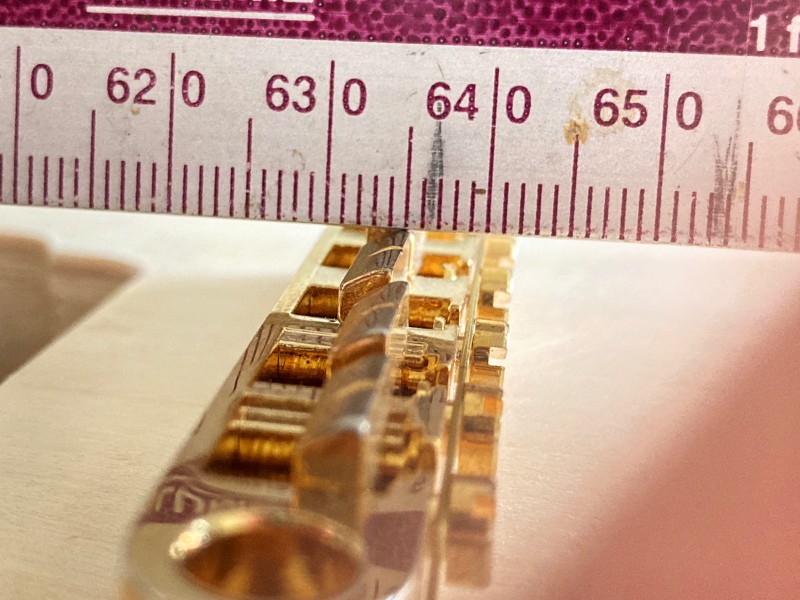

The next thing was to check the neck angle. The neck itself had quite a severe back-bow, which took about 1.5 turns of the truss-rod to correct. Once the neck was flat, I set it in place and ran a straight edge along it so I could see what sort of height I had at the bridge position.

Luckily there's plenty of height. Possibly too much, so I may well try reducing the neck angle very slightly as I don't like bridges sitting too high on posts for stability reasons.

So that's it to start with.

Reply With Quote

Reply With Quote