Since I can't get to any of my instrament kits or scatch biult materials due to the lockdown, I have been working on some jigs both before the lockdown and during.

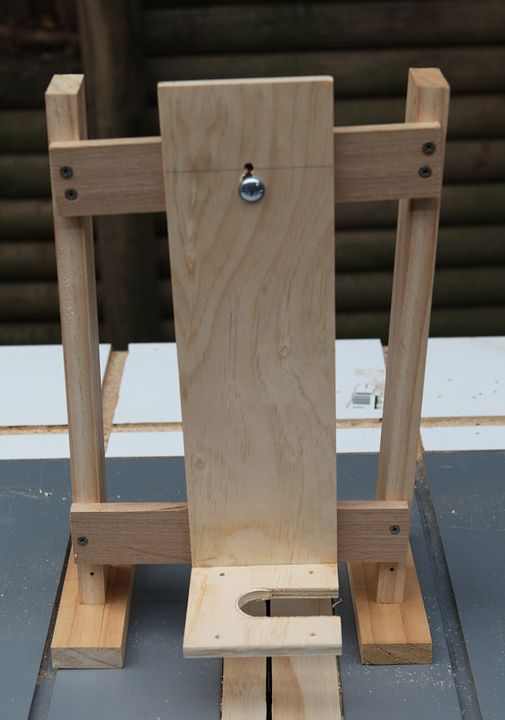

I wanted to make a fret board radius sanding block. the first jig I did wasn't great:

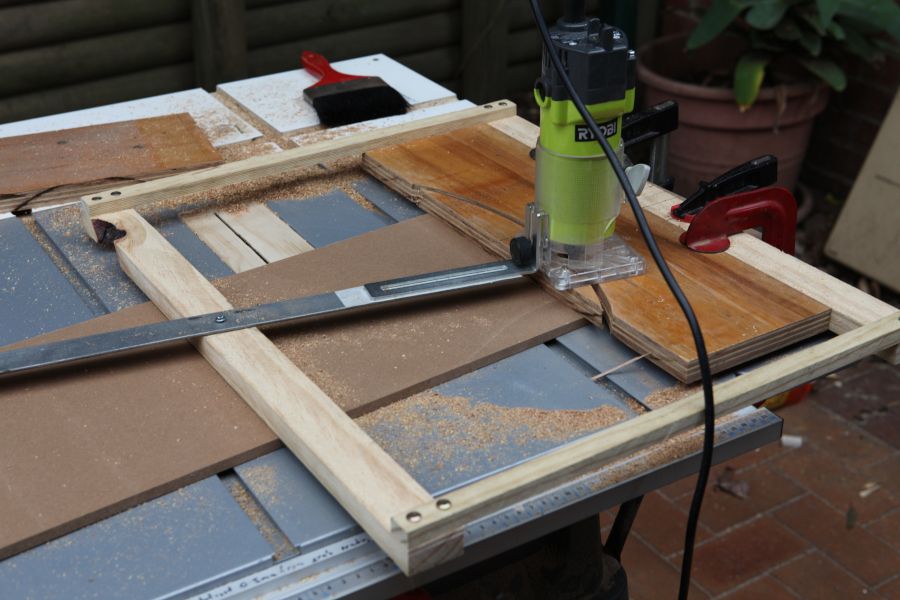

It didn't end up with the radius in the center of the block, it was a bit wobbly and the bit I used was a round nose bit. I ended up with a series of gouges instead of a nice smooth surface. So, I had another crack. Sometimes to make a jig you first have to....... make a jig!:

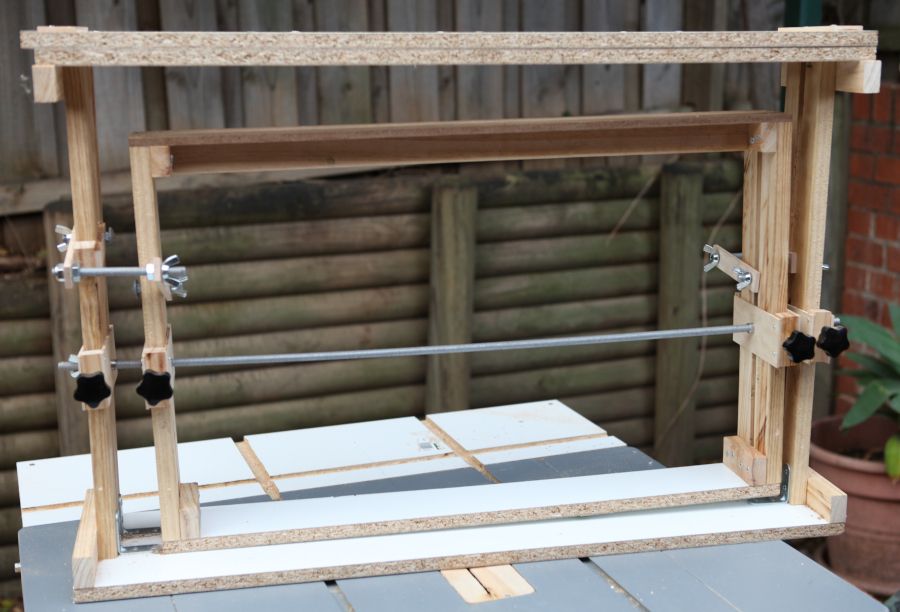

to end up with:

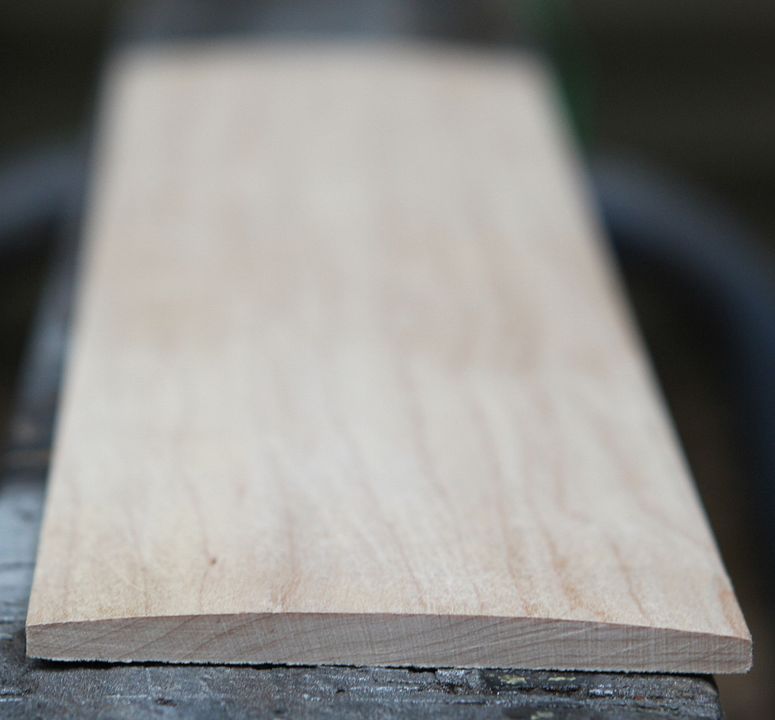

which was used to make:

The shaping block has 60 grit which will soon become obsolete because of this:

which can be used to do this:

I got the plans from the Kappi Guitars website. I'm in the process of making a smaller block with velcro so that I can use round pads to smooth the fretboard after radiusing.

The jig can also do fretboards with changing radiuses. This soon will be an obsolete jig as you will see when I get to try out the next jig I've just about done.

.jpg?width=960&height=720&fit=bounds)

Reply With Quote

Reply With Quote