i have used brass plates under the PUPs in this build: https://www.buildyourownguitar.com.a...t=7399&page=17

i havenít noticed any issues, and the blocks I used go the full width of the PUP cavity. If you are only filling the screw rebate I donít see it should be a problem, especially with aluminium.

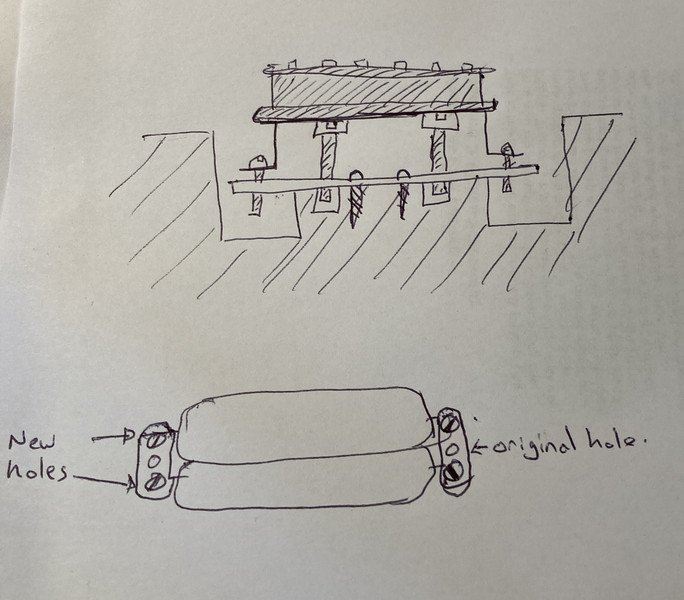

I am also going to use some M2 threaded brass inserts as PuP mounts for a later build. They are similar to these ones used in my current strat build: https://www.buildyourownguitar.com.a...t=8238&page=14

Reply With Quote

Reply With Quote otherwise I think wood was just too weak for the screws and springs and it would take damage some day and be without use...so metal sounds a better solution

otherwise I think wood was just too weak for the screws and springs and it would take damage some day and be without use...so metal sounds a better solution

I hope

I hope