So, the story thus far.....

There are a number of different ways the headstock mod could be done. The more simple way would be to cut the heatstock parallel the width of the nut, if the bit left is a bit too short, the end cut strait (either 90deg of at an angle, but a strait cut). The extra material needed then glued to the reminants of the original headstock. Then the new headstock shape cut.

The elegant way of doing it would be to cut the original headstock off, carefully remove the remaining part of the original headstock, exposing the scarf joint. Care must be taken not to damage the truss rod. Using a large enough chunk of timber, create a new headstock, including a short section of the neck, and scarfing that in, effectivly replacing the original headstock. Obviously you would need to rout the neck part of the new headstock to accommodate the truss rod. Ironicaly, shortly after thinking of this approach, I saw a YouTube video of a headstock repair on a Les Paul doing exactly this!

And then there's what I did (if there's a hard way of doing something, I'll find it) Here's what I had to work with:

As you can see they blended the headstock smoothly into the neck. Looks good, but a pain for what I had planned. This was my solution:

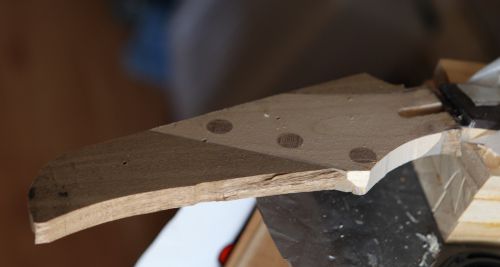

Here's the headstock paddle after I had added the extra timber:

As you can see, it's a bit of a mess. Both for strength, and the fact that the fit was not good enough for wood glue, I used epoxy with a special purpose filler to create a glue. A bit of time with a cabinet scraper would have resulted in a wood glue appropriate fit. I could not use clamps on this thing, so I had to use green masking tape. The tape I use has some stretch, so some clamping pressure could be applied from the tape. The down side is that the timber did move a little, so surface was not 100% parallel with the face of the headstock. The other problem is that the squeese out is trapped under the tape, so it leaves a mess. <shrug> it will sand out. The more astute of you will notice there was an extra bit of timber added to the end.

"So, did you blow a sneaker like everyboby says, or did you just **** up?"........"No Darryl, I just ****ed up...."

That's it for now folks!

Reply With Quote

Reply With Quote

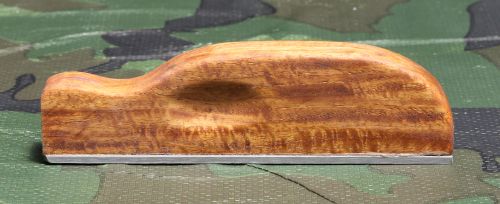

after sanding back smooth, it looked like this:

after sanding back smooth, it looked like this:

.

.

. That's it so far... I believe my next project is on it's way on a slow boat from China.

. That's it so far... I believe my next project is on it's way on a slow boat from China.