i have used brass plates under the PUPs in this build: https://www.buildyourownguitar.com.a...t=7399&page=17

i havenít noticed any issues, and the blocks I used go the full width of the PUP cavity. If you are only filling the screw rebate I donít see it should be a problem, especially with aluminium.

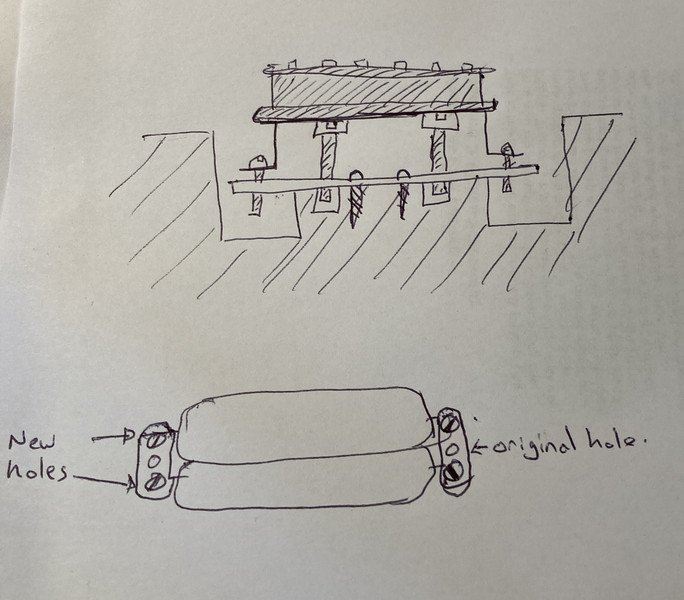

I am also going to use some M2 threaded brass inserts as PuP mounts for a later build. They are similar to these ones used in my current strat build: https://www.buildyourownguitar.com.a...t=8238&page=14

Reply With Quote

Reply With Quote otherwise I think wood was just too weak for the screws and springs and it would take damage some day and be without use...so metal sounds a better solution

otherwise I think wood was just too weak for the screws and springs and it would take damage some day and be without use...so metal sounds a better solution

I hope

I hope ed up the whole thing...but at the end it worked...I am glad the body will be black, so my mistakes will be invisible after grainfilling and modeling with wood putty...

ed up the whole thing...but at the end it worked...I am glad the body will be black, so my mistakes will be invisible after grainfilling and modeling with wood putty...