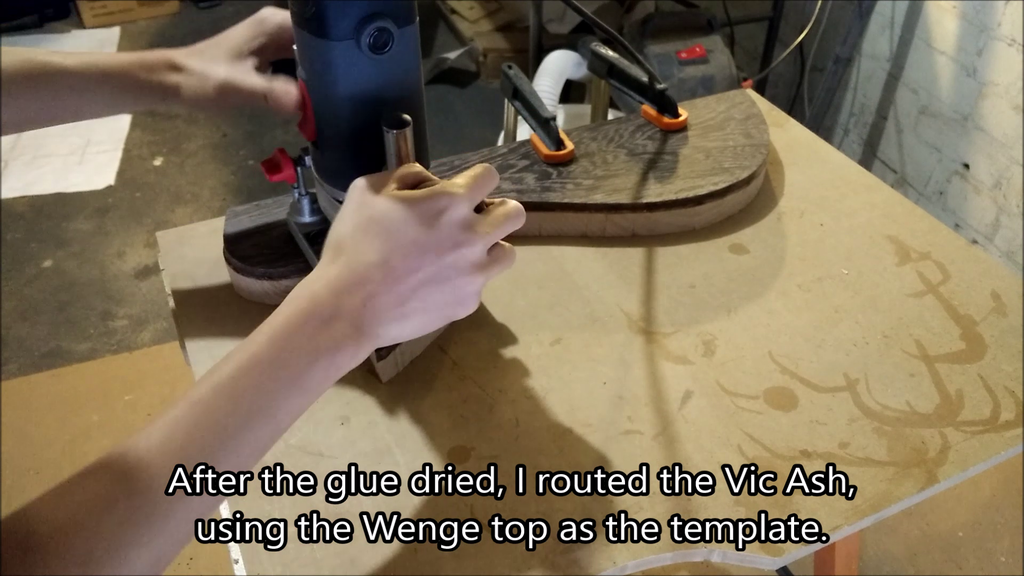

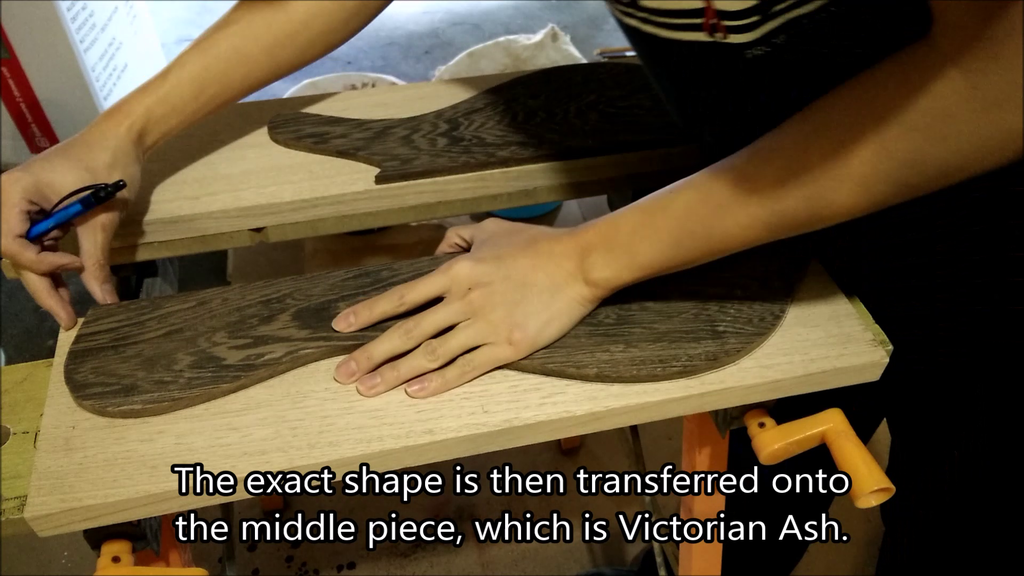

Once I was happy with the wenge top, I transferred the outline onto the second piece, the Victorian ash.

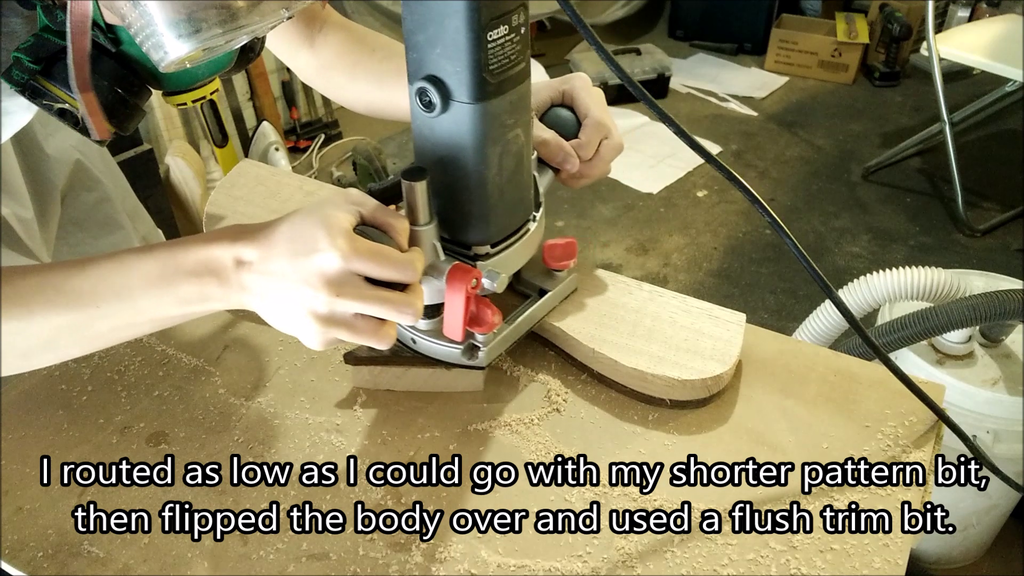

Then cut it out. The Vic ash is thicker at 21mm so my jigsaw was struggling towards the end. Man I wished I had a bandsaw!

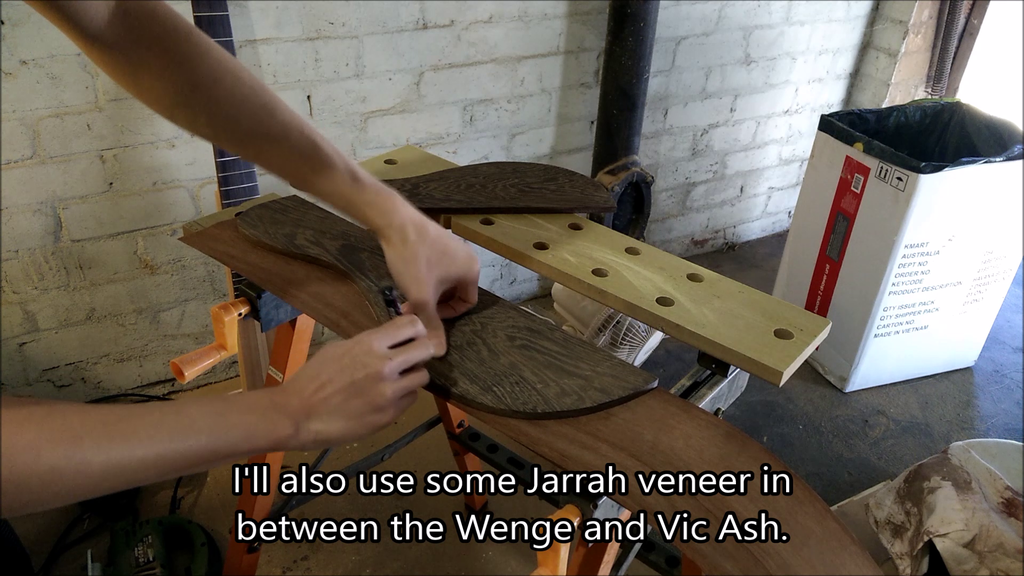

I also decided to use a Jarrah veneer in between the wenge and the Vic ash. This provides a nice contrast which should hopefully show up once I start carving the top.

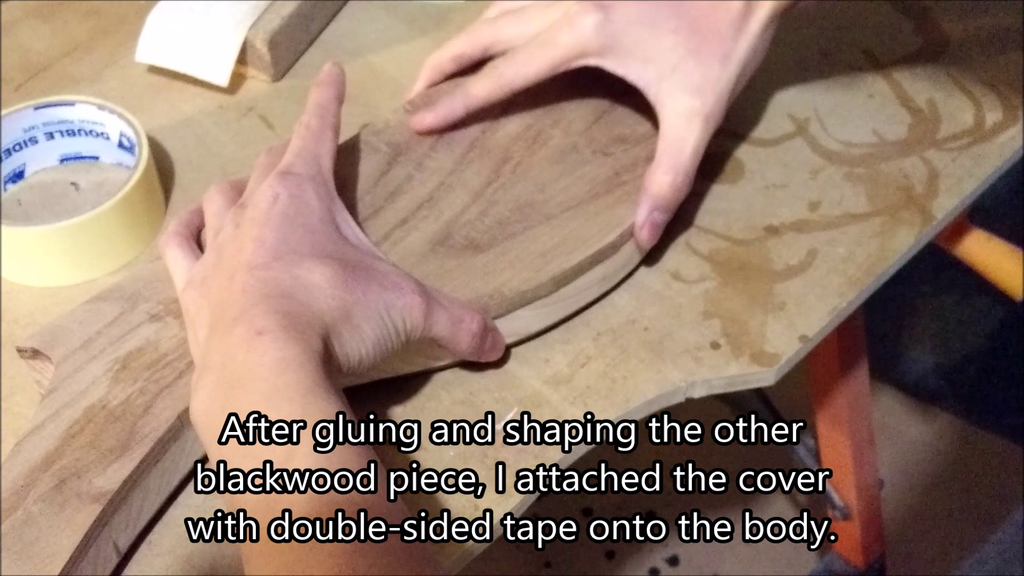

Here's a pic of the first 3 layers.

Reply With Quote

Reply With Quote